Dry Bulk Material Discharging

NBE bulk material discharging projects contribute such high levels of effectiveness and efficiency to our customers' processing operations because every NBE project is engineered-to-application. NBE engineered-to-application projects begin by recognizing the comprehensive influence of an NBE project. There are pre-build influences, like constructability reviews, and regulatory assessments; and there are site-related influences like modular construction, and SAT protocols that are every bit as important to the application engineering as the materials of construction and performance requirements themselves. These are not the applications for a force-fit, build-to-order model or a best-guess, engineered-to-order effort. For our processing customers, AEC firm partners, and third-party integrators, NBE engineered-to-application projects are the fastest way to total process performance.

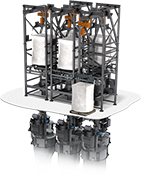

Bulk Bag Dischargers

See actual NBE bulk bag discharging projects in operation. See how optimal upstream performance provides reliable, repeatable downstream throughput. These NBE bulk bag discharging projects address complex engineering challenges, including: clean-in-place applications, highly caustic materials, and integration to SCADA systems.

Bulk Container Dischargers

Watch NBE bulk container discharging projects bring efficient and controlled introduction of dry bulk material to actual processing operations. See NBE conveying and material conditioning increase yield with no change in run rate; see how design engineering speeds changeovers while reducing material waste; and, see how limiting human interaction is a good thing when rates and weights are too much.

Drum Dischargers

See how NBE drum discharging projects are engineered beyond just the basic functional requirements of the application to, also, provide process advantages that benefit the greater enterprise. Physical ergonomic design reduces operator risks while improving labor allocations; dust control meets hygienic zone requirements while reducing material waste; and, hygienic design speeds changeover while simplifying internal controls.

Bag Break Stations

See how NBE bag break stations enable safe and accurate, manual introduction of packaged dry materials into processing operations. Whether operators are emptying 50-pound multiwall bags, 5-gallon buckets, or tote boxes, NBE bag break stations are designed to simplify the infeed of primary materials into short-run batches, or infeed of minor ingredients into high-volume production. NBE application-specific engineering provides integration of these bag break stations with downstream process equipment, including: mixers, hoppers, and conveying systems.