-

45-degree Bin Cone Slope

Designed for free-flowing dry, bulk materials; the 45-degree bin cone slope of an NBE surge bin facilitates

proper material flow to the bin bottom for supply to downstream processes.

-

60-degree Bin Cone Slope

When handling semi-free flowing dry, bulk materials; the 60-degree bin cone slope of an NBE surge bin helps

prevent material bridging or ratholing. The steep cone slope naturally directs material to the bin bottom

for discharge downstream.

-

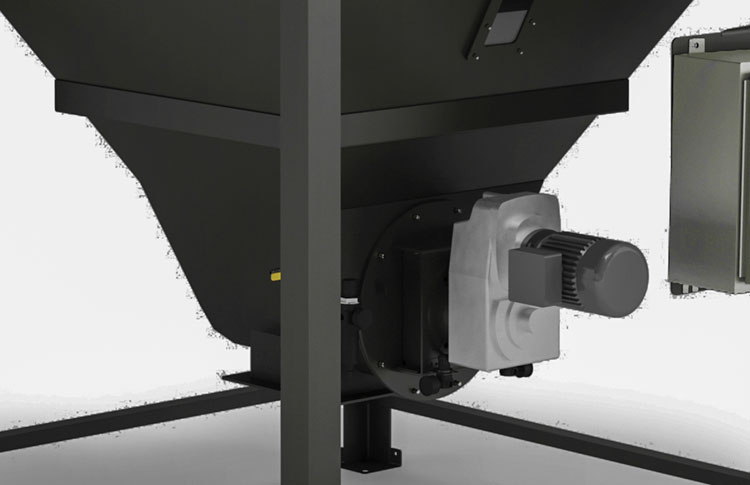

14-gauge Carbon Steel Bin Construction

High-strength bin body construction aids in stable material loading and staging in NBE surge bins. Surge bin

seams are sealed with continuous welds that are ground smooth to remove irregularities. The 7-gauge, formed

bin legs and cross bracing provide long-lasting service, and protect process materials when totes, gaylords,

and other intermediate bulk containers cannot.

-

NBE Graphite Painted Exterior Finish

Specially formulated for industrial environments to provide excellent resistance to impact and abrasion,

chemicals, and mildew.

-

Sidewall Stiffening Ribs

For materials with demanding bulk densities, for applications with challenging duty cycles; NBE surge bins

are available with performance-proven sidewall stiffening ribs. Tri-angled construction aids in sidewall

stability; angled top surface resists material accumulation.

-

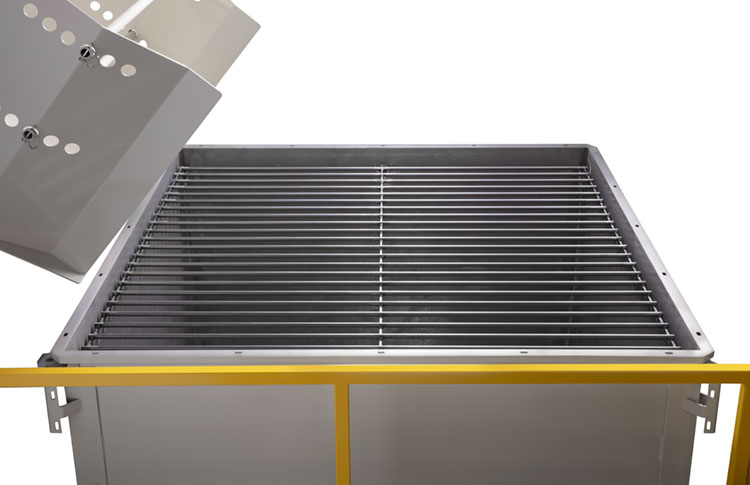

Cover with Pre-drilled Vacuum Receiver Mount and Access Hatchway

Pre-drilled to accommodate customer-specific receiver or cyclone bolt-hole patterns, each NBE surge bin

arrives on-site ready for immediate process integration. The center-positioned mounting plate is

reinforced with cross members located below the bolt-on top cover. The top cover includes a 12-inch

by 9-inch, hinged inspection hatchway.

-

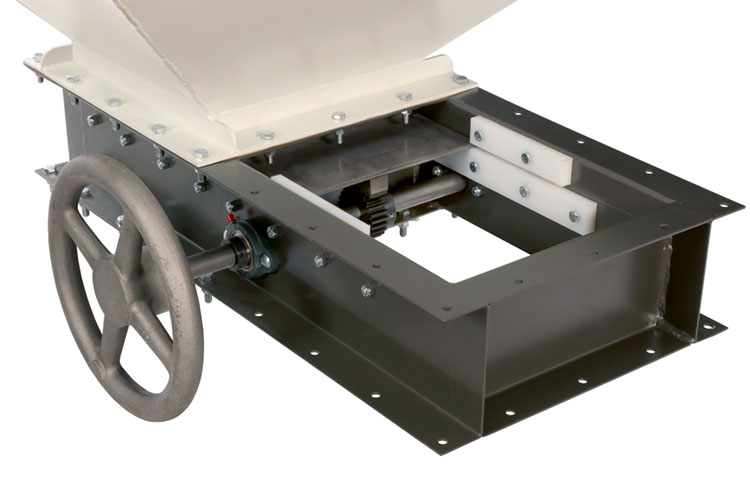

16.25-inch OD x 12.00-inch ID, Square, Carbon Steel Discharge Flange

Heavy-gauge construction provides a strong and stable interface for process equipment and components.

The standard, square flange dimension simplifies integration; eliminating the need for complicated,

on-site transition fabrications.

-

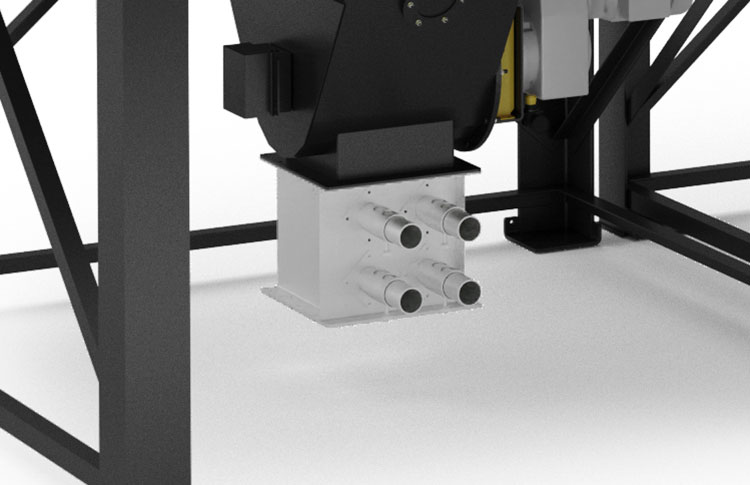

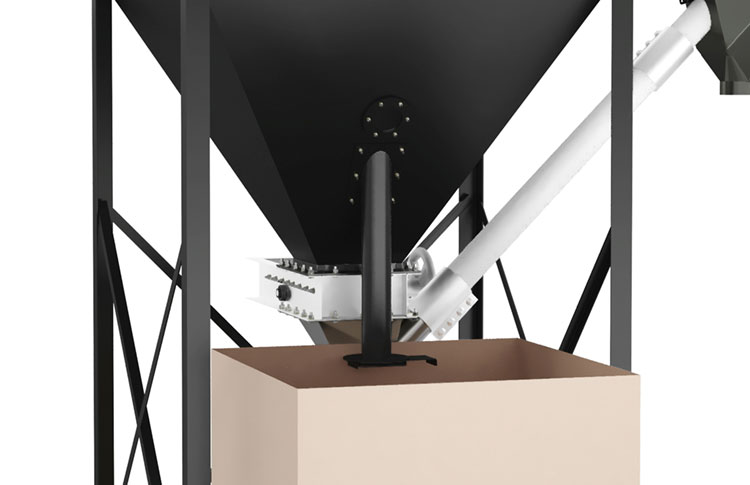

48.00-inch Minimum Width Access Below Bin for Gaylords, Hoppers, Totes

Easily position gaylords, hoppers, or totes below the drop tube or discharge flange of the surge bin.

Simplify container filling directly from surge bin. Other standard widths available based on surge bin capacity.

-

Pre-drilled Bolt-hole Pattern for Drop Tube Mount

NBE provides a pre-drilled bolt-hole pattern to simplify aftermarket add-on of a drop tube. Located on the

IBC access side of the bin cone, the drop tube mount is easily within operator reach.

-

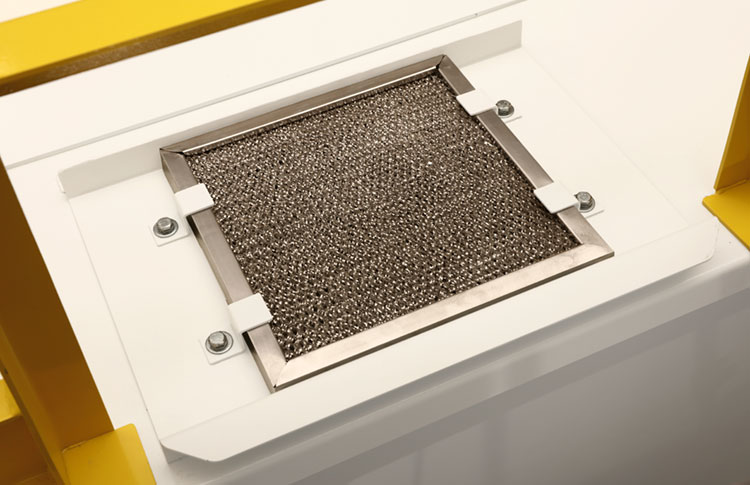

4-inch Diameter View Window

For visual monitoring of material levels and verifying of bin contents, view windows are center-mounted in the

surge bin sidewall for high-level visibility, and in the surge bin cone wall for low-level visibility. Standard

quantity and location of view windows depends on surge bin capacity.

-

High- and Low-level Sensor Ports

To enable the addition of an aftermarket level sensor system, two, 1.25-inch, NPT couplings are fabricated into

the surge bin; one at the high-level location of the sidewall and one at the low-level location of the cone.

-

Lifting Lugs

Engineered and fabricated to provide lift points for surge bins that are properly rigged and emptied of material,

these lifting lugs are available on NBE surge bin models that are not designed for applications requiring portability.

-

Bolt-down Foot Pads

When material processing applications require surge bins be anchored to the floor, NBE heavy-gauge, seam-welded,

bolt-down foot pads provide strong, and stable points for securing stationary surge bins in location.