Applied Engineering: The Requirement of Process Conveying Performance

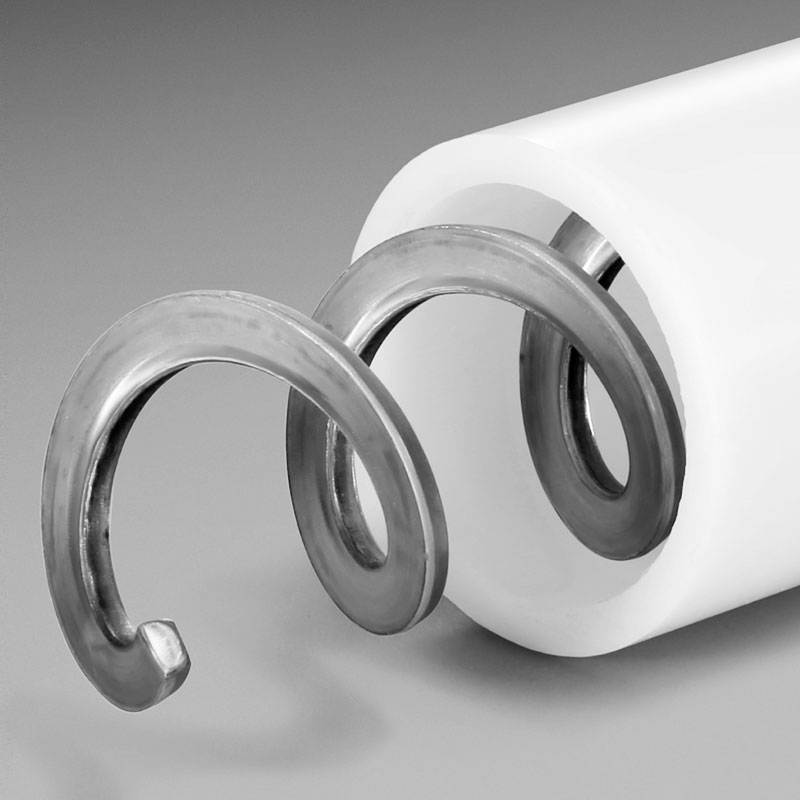

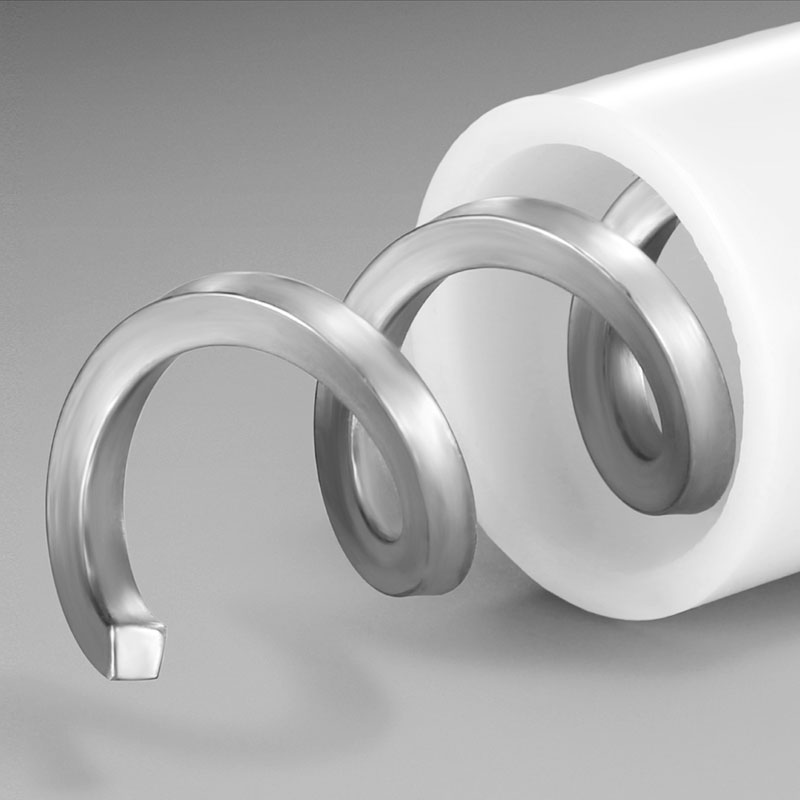

The principle of helicoid motion as a processing and production conveying method is widely used. Yet, National Bulk Equipment has advanced this science by combining our application-specific bulk material handling expertise with market-dominant build specifications and materials of construction. NBE flexible screw conveying systems provide sustained conveying performance, at designed capacities, of the most demanding materials and bulk densities.