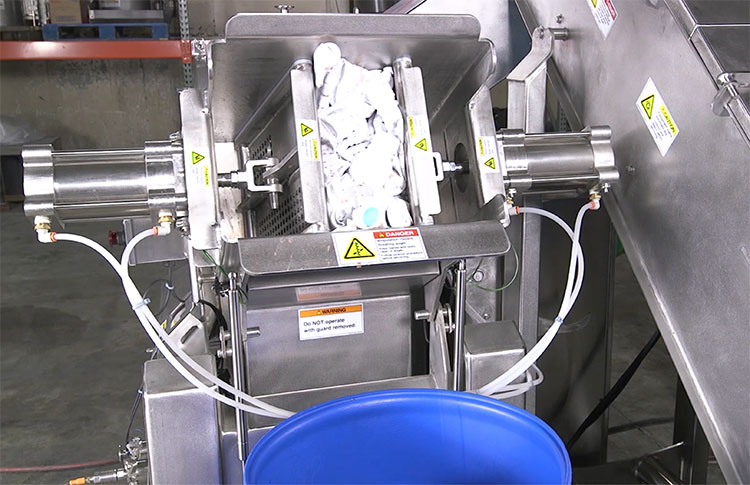

Controlled, Sanitary Recovery of Packaged Liquids and Packaging Materials

Liquid-product recovery events will occur, whether caused by mislabeling, off-spec filling, overruns, or other process defects. When product and package recovery is necessary, NBE reclaim systems for liquid-filled packages enable packaging and processing operations to reduce product loss, reduce or eliminate packaging waste, and protect corporate and product brands. Be it PET bottles, aluminum cans, coated paperboard, flexible packaging, poly-based tubes, or other packaging or contents, NBE engineered-to-application (ETA) project execution ensures our process-specific insights in the design, engineering, and automation of liquid-product reclaim equipment are leveraged to improve your total process effectiveness.