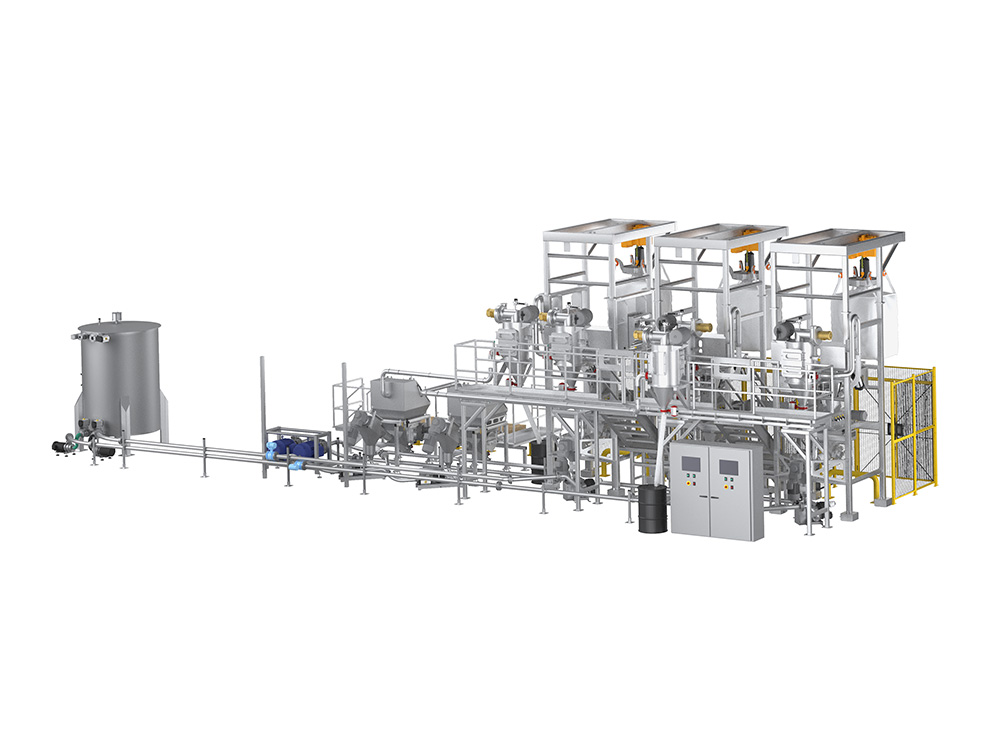

Reduce Downstream Process Concerns, Improve Upstream Product Supply Efficiency

NBE slurry processing and handling systems, and solution processing and handling systems each leverage the advantages of NBE fullstream project engineering with the performance-proven contribution of NBE engineered-to-application equipment. Regardless of the application, from food and beverage to pharmaceuticals, or health and beauty to building products, NBE slurry or solution systems ensure downstream processing or packaging operations are accurately and repeatedly supplied homogeneous product at designed rates.