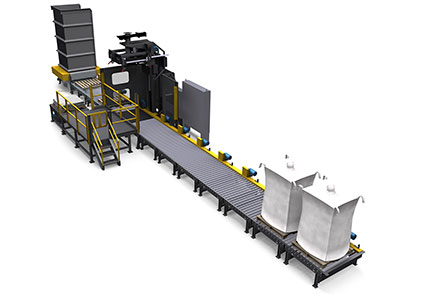

High-performance Equipment Built for Demanding Applications

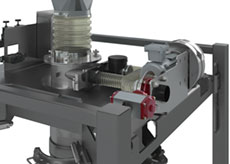

NBE bulk bag filler systems are engineered for bulk material processing and bulk material packaging applications requiring high-performance operation; where reliable and repeatable duty cycles, rates, accuracy, and equipment effectiveness are crucial — regardless of process material characteristics. NBE bulk bag filler systems operate on a process-specific structural framework chassis. The NBE controls and automation architecture is integrated throughout the chassis to create a combined construction and controls infrastructure. This NBE integrated construction and controls infrastructure improves operator interaction with the system, provides more comprehensive and actionable performance data, and reduces total cost of ownership.