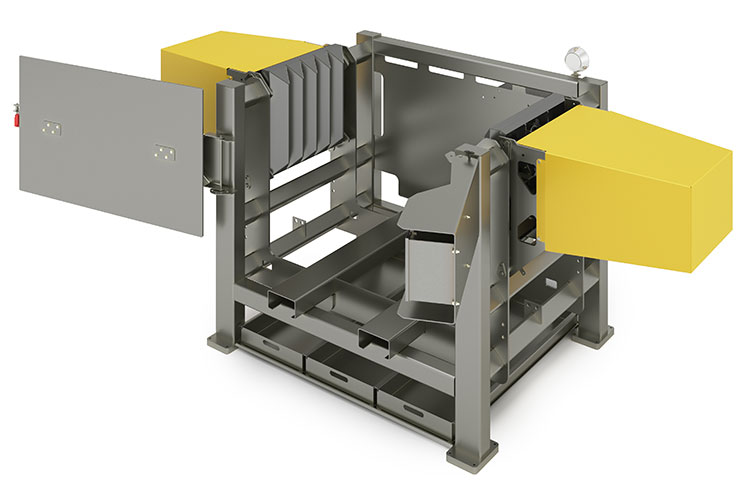

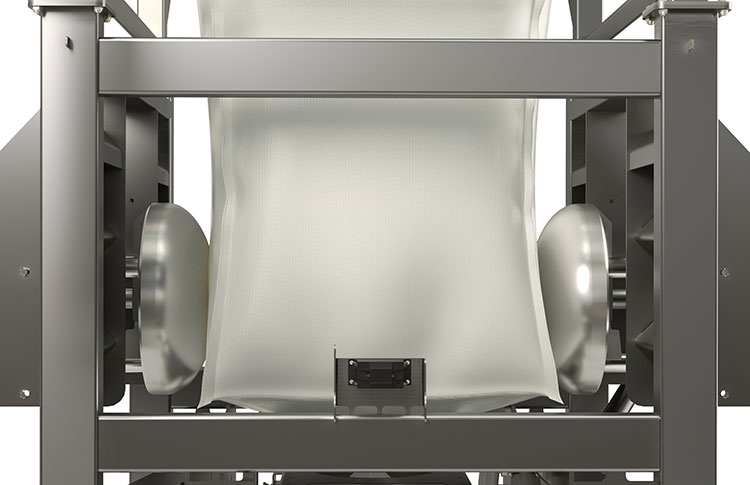

Reduce Rock-hard Material in Bulk Bags to Optimal Size for Downstream Supply

National Bulk Equipment bulk bag conditioner systems are performance-built to bring material conditioning power, in excess of 29,000 pounds of hydraulic force, to material in bulk bags that is too agglomerated and too large to discharge from the bulk bag. NBE bulk bag conditioners are engineered to automatically reduce rock-hard material in the bulk bag to the optimal size necessary to ensure uninterrupted discharge from the bulk bag to integrated, downstream equipment. Eliminate material-supply reliability issues common with mis-applied mechanical systems; avoid safety concerns caused by manual bag conditioning attempts. NBE bulk bag conditioner systems enable downstream efficiency and production yield through upstream operating performance and longevity.