Reliable and Repeatable Availability, Throughput, and Finished-product Quality

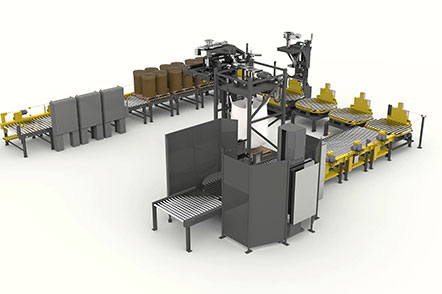

NBE drum filling systems provide dry material processing operations a highly reliable, extremely accurate bulk material packaging system for filling, weighing, lidding, and conveying fiber drums, plastic drums, or steel drums. Each NBE drum filling system is engineered to the unique application requirements of the operation; regardless of duty cycle, process environment, or material characteristics demands. The integration of the NBE structural framework chassis with the NBE controls and automation architecture combine to ensure NBE drum filling systems perform at optimal uptime availability, without material waste or rework, and at improved throughput efficiency levels.