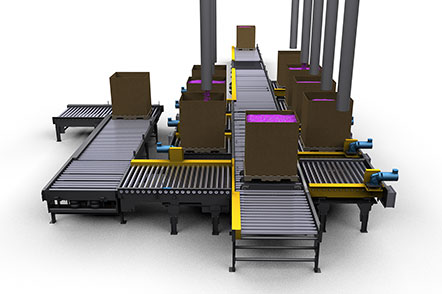

Leveraging Production Effectiveness for Bulk Material Processing and Packaging

NBE bulk container filling systems bring optimal production effectiveness to processing and packaging operations handling dry bulk materials. Engineered to the specific performance requirements of each application, NBE bulk container filler systems leverage their integrated construction and automation infrastructure to ensure production stays running at designed rates, throughput levels, and finished quality targets. The dominant materials of construction and build specifications of NBE bulk container filling systems easily withstand severe operating environments and demanding duty cycles. NBE controls and automation architecture pushes control functionality farther out, and deeper into container filler operations to optimize its total line throughput and deliver standard, system-wide, data reporting.