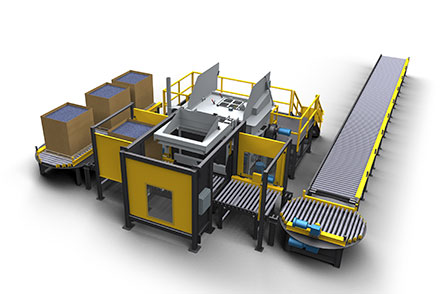

Upstream Performance Improving Downstream Efficiency

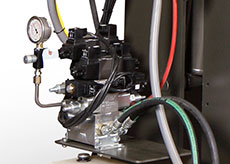

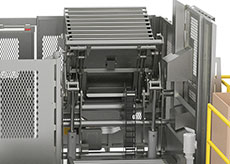

NBE bulk container discharger systems provide controlled discharge, and complete unloading, of dry bulk materials from totes, gaylords, bins, or other intermediate bulk container types. NBE bulk container discharging systems are engineered and constructed to withstand the harshest plant environments and demanding duty cycles. Together, with NBE automation and controls, this integrated construction and automation infrastructure enables dry bulk material processing operations to safely discharge, even the most hard-to-handle materials, while limiting operator interaction, reducing dusting, protecting product from contamination, and eliminating material waste. NBE bulk container discharging systems aid downstream process performance by ensuring a reliable, accurate material supply.